How Portable Building Anchors Help With Fast and Reliable Site Setup

Wiki Article

How Anchoring Solution Enhance Safety and Stability in Different Industries

Anchoring systems are vital for making certain security and stability across numerous sectors. They provide important support for structures, equipment, and personnel, mitigating dangers associated with dynamic conditions and lateral pressures. From construction websites to maritime environments, these systems serve diverse features. Their performance is typically taken for provided, yet the subtleties of their application can substantially impact functional success. Comprehending their value reveals deeper insights right into industry security criteria and practices.The Relevance of Anchoring Systems in Safety And Security Protocols

Frequently neglected, anchoring systems play a crucial role in ensuring security throughout different markets. These systems provide stability and assistance for frameworks, tools, and personnel, therefore minimizing the risk of mishaps and injuries. In settings such as construction sites, maritime operations, and industrial facilities, reliable anchoring assurances that hefty equipment and scaffolding remain safe, avoiding devastating failings. Additionally, proper anchoring systems can boost the effectiveness of individual protective equipment, such as harnesses, by securing them to secure points, which is crucial for employees operating at heights. Using reputable anchoring procedures promotes a safety and security culture, where both management and workers prioritize threat mitigation. Eventually, the integration of properly designed anchoring systems right into safety procedures is crucial for maintaining operational integrity and safeguarding human life, highlighting their relevance in day-to-day precaution throughout varied areas.Kinds Of Anchoring Systems Made Use Of in Building

In addition, ground supports are important for supporting frameworks in tough surface, giving resistance versus side forces. Tiebacks and soil anchors are employed in excavations and retaining wall surfaces to improve security against dirt stress. Each sort of anchoring system is designed to meet specific load needs and environmental problems, adding to the overall safety and longevity of construction tasks.Securing Solutions for Maritime Stability

Effective anchoring remedies are important for making certain maritime security, particularly in dynamic marine environments. These options play a critical function in safeguarding vessels, offshore systems, and floating frameworks against unpredictable forces such as waves, currents, and wind. Different kinds of anchors, including standard stockless anchors, drag anchors, and suction anchors, are employed based on details operational demands and seabed conditions.The layout and option of anchoring systems are influenced by variables such as water deepness, soil make-up, and environmental conditions. Advanced technologies, including vibrant positioning systems and real-time tracking, additionally boost the effectiveness of anchoring solutions. By giving a steady structure, these systems considerably minimize the threat of tipping over or wandering, consequently guaranteeing the security of employees and freight. Ultimately, robust anchoring remedies add to the functional performance and longevity of maritime assets, highlighting their importance in the maritime market.

Aerospace Applications: Maintaining Airplane Secure

In the aerospace market, ensuring the safety and security of airplane includes various tie-down techniques and freight securing approaches. Compliance with security laws is critical to keeping stability throughout ground procedures and transport. These practices are necessary for protecting against accidents and making certain the safety of both the aircraft and its residents.Aircraft Tie-Down Techniques

While the safety of airplane is critical, proper tie-down methods act as an important component in ensuring security during ground operations. Airplane tie-downs include safeguarding the airplane to the ground making use of ropes, chains, or specialized bands, stopping unwanted motion because of wind or other environmental variables. Reliable techniques include making use of proper support factors and using an adequate number of tie-downs based upon the airplane's dimension and weight. Routine evaluations of tie-down equipment are necessary to guarantee reliability and efficiency. In addition, understanding neighborhood climate condition can assist the choice of products and techniques used for safeguarding aircraft. Inevitably, executing audio tie-down practices enhances functional safety and prevents damages throughout durations of lack of exercise.Cargo Protecting Approaches

Cargo protecting approaches play a necessary function in maintaining the honesty and security of airplane throughout transportation. Efficient systems guarantee that cargo continues to be steady and protected throughout the flight, decreasing the threat of movement that might cause harm or mishaps. Common techniques consist of using cargo internet, bands, and specialized locking devices created to withstand the forces experienced throughout takeoff, flight, and touchdown. The implementation of these methods involves careful planning and consideration of the cargo's weight distribution and center of mass. Additionally, tools such as tons binders and edge protectors enhance the overall effectiveness of safeguarding methods. By utilizing these methods, the aerospace sector significantly lowers possible hazards related to carrying goods, ultimately guarding both the airplane and its freight.Safety Laws Compliance

Guaranteeing compliance with safety and security regulations is crucial for preserving the safety of aircraft and their freight. In the aerospace industry, strict adherence to laws established by controling bodies, such as the Federal Aeronautics Management (FAA) and the International Civil Air Travel Organization (ICAO), is vital. These regulations mandate the usage of dependable anchoring systems to secure cargo and avoid moving during trip, which can cause accidents. Appropriate training for personnel in using these systems is likewise needed to confirm their efficiency. Regular inspections and upkeep of securing equipment even more improve compliance and safety and security. By adhering to these policies, the aerospace industry can greatly lower dangers, safeguard lives, and maintain operational stability in flight.Manufacturing Safety And Security: Function of Anchoring in Manufacturing

In the domain name of manufacturing, securing systems play an important role in making sure devices stability and avoiding workplace mishaps. By firmly securing equipment, these systems not only improve safety yet also add to operational performance. Efficient securing practices can considerably reduce the danger of occurrences, promoting a safer workplace.Equipment Security Guarantee

The production environment frequently involves hefty machinery and facility tools, the effectiveness of anchoring systems plays a significant role in preserving tools security. Properly set up supports minimize resonances and protect against devices from changing throughout procedures. This security is crucial for both the functionality of equipment and the general effectiveness of manufacturing processes. Furthermore, well-anchored tools decreases damage, extending the lifespan of pricey possessions. In environments where precision is extremely important, such as production line, the assurance of security supplied by securing systems improves functional precision. Incorporating durable anchoring remedies into making configurations not only safeguards devices but additionally promotes a trustworthy production landscape, eventually contributing to better outcome and performance.Stopping Office Accidents

Securing systems significantly add to preventing work environment accidents in producing settings. By securing machinery and tools, these systems reduce the risk of tipping, falling, or moving during operation. This security is essential, as unanchored tools can cause serious injuries amongst workers and damage to building. On top of that, securing systems enhance the efficiency of safety and security protocols, as they give a dependable structure for precaution such as guardrails and security nets. Regular inspections and upkeep of anchoring systems are essential to guarantee their honesty, therefore promoting a society of safety within the office. Ultimately, a robust anchoring system is a fundamental component in producing a much safer production setting, lowering the likelihood of accidents and promoting general work environment safety.Enhanced Operational Effectiveness

Enhancing functional performance in manufacturing relies significantly on efficient securing systems. These systems supply stability to machinery and devices, minimizing resonances and movement during production processes. By making sure that devices and elements remain firmly in position, anchoring systems reduce the danger of operational delays triggered by devices imbalance or failure. This dependability enables Site Security Anchors for smoother process and enhanced efficiency, as employees can concentrate on their tasks without continuous adjustments or disruptions. Additionally, reliable securing adds to the longevity of machinery, reducing maintenance costs and downtime. As an outcome, suppliers can achieve higher outcome rates and boosted source use, inevitably bring about higher success and an my latest blog post one-upmanship on the market.

Advancements in Anchoring Modern Technology

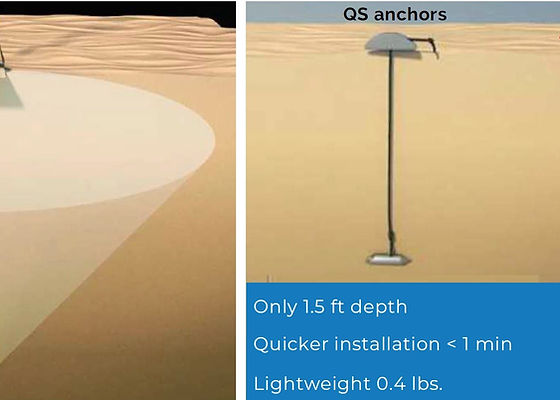

As the demands for security and security in numerous sectors raise, innovations in anchoring innovation have actually emerged to deal with these difficulties. Modern anchoring systems are now created with innovative products and design strategies, boosting their sturdiness and efficiency. Developments such as clever sensors and automated surveillance systems enable real-time assessment of anchoring efficiency, guaranteeing optimal safety actions are kept.In addition, lightweight composite materials have actually changed conventional steels, decreasing the general weight of anchoring systems while enhancing toughness. Modular designs give flexibility, enabling for very easy modifications and modifications to satisfy certain functional requirements. Furthermore, environment-friendly anchoring options are acquiring traction, minimizing ecological effect while guaranteeing durable efficiency.

These developments not just enhance the dependability of securing systems however also resolve the progressing requirements of varied industries, including construction, marine, and renewable energy fields. Such technologies lead the way for more secure and much more effective procedures throughout various applications.

Instance Studies: Effective Application of Anchoring Systems

The innovations in anchoring modern technology have brought about noteworthy instance studies showcasing effective implementations across numerous sectors. In the building industry, a significant project made use of a new sort of deep structure securing system, which enhanced stability in difficult dirt problems. This advancement considerably reduced negotiation issues and ensured safety and security during building, eventually causing timely job conclusion.In a similar way, in the maritime sector, a shipping company adopted sophisticated mooring systems that enhanced vessel stability during negative weather conditions. This implementation resulted in a significant decline in accidents and cargo losses, highlighting the relevance of trusted anchoring in unpredictable settings.

In addition, in the wind power field, securing systems have actually been crucial in protecting overseas generators against strong currents, demonstrating their role in lasting power production (Lightweight Anchoring Systems). These study jointly illustrate just how efficient anchoring services add to safety and security, efficiency, and lasting feasibility throughout diverse sectors

Often Asked Questions

How Do Anchoring Systems Affect Overall Task Timelines?

The effectiveness of project timelines can be significantly influenced by securing systems. Proper anchoring lowers delays by ensuring stability, minimizing threats, and assisting in smoother operations, eventually adding to prompt job conclusion and improved productivity.Are There Particular Rules Governing Anchoring Solutions?

Particular policies controling anchoring systems exist across various industries, making sure compliance with safety and security standards. Lightweight Anchoring Systems. These regulations typically concentrate on installment, maintenance, and style, aimed at minimizing dangers and improving overall functional security and safety

What Products Are Frequently Utilized in Anchoring Equipments?

Usual materials used in securing systems include high-strength steel, galvanized iron, synthetic ropes, and composite products. These elements are picked for their longevity, resistance to environmental factors, and ability to offer dependable assistance in different applications.

How Often Should Anchoring Equipments Be Examined?

Inspection regularity for anchoring systems generally relies on use and ecological problems. Generally, it is advised to carry out inspections every 6 months, with more frequent sign in extreme settings or adhering to significant events influencing stability.What Are the Expenses Related To Mounting Anchoring Systems?

The expenses connected with mounting anchoring systems differ considerably based upon variables such as materials, design intricacy, and labor demands. Correct budgeting is vital to assure reliable application and compliance with safety and security regulations in relevant markets.Anchoring systems are crucial for making sure safety and security and security across numerous industries. Frequently overlooked, anchoring systems play a vital duty in ensuring safety and security across numerous sectors. In enhancement, securing systems boost the performance of safety and security protocols, as they offer a reliable foundation for safety procedures such as guardrails and safety and security webs. Normal inspections and maintenance of anchoring systems are vital to ensure their honesty, thereby cultivating a society of safety and security within the official source work environment. Particular policies regulating securing systems exist throughout numerous markets, ensuring compliance with security requirements.

Report this wiki page